The Rise of Smart Factories: IoT Integration in Manufacturing

Ever since the advent of the Internet of Things (IoT), industries and businesses around the world have been harnessing its potential to revolutionize their operations. One area that has seen significant transformation is manufacturing, with the rise of smart factories.

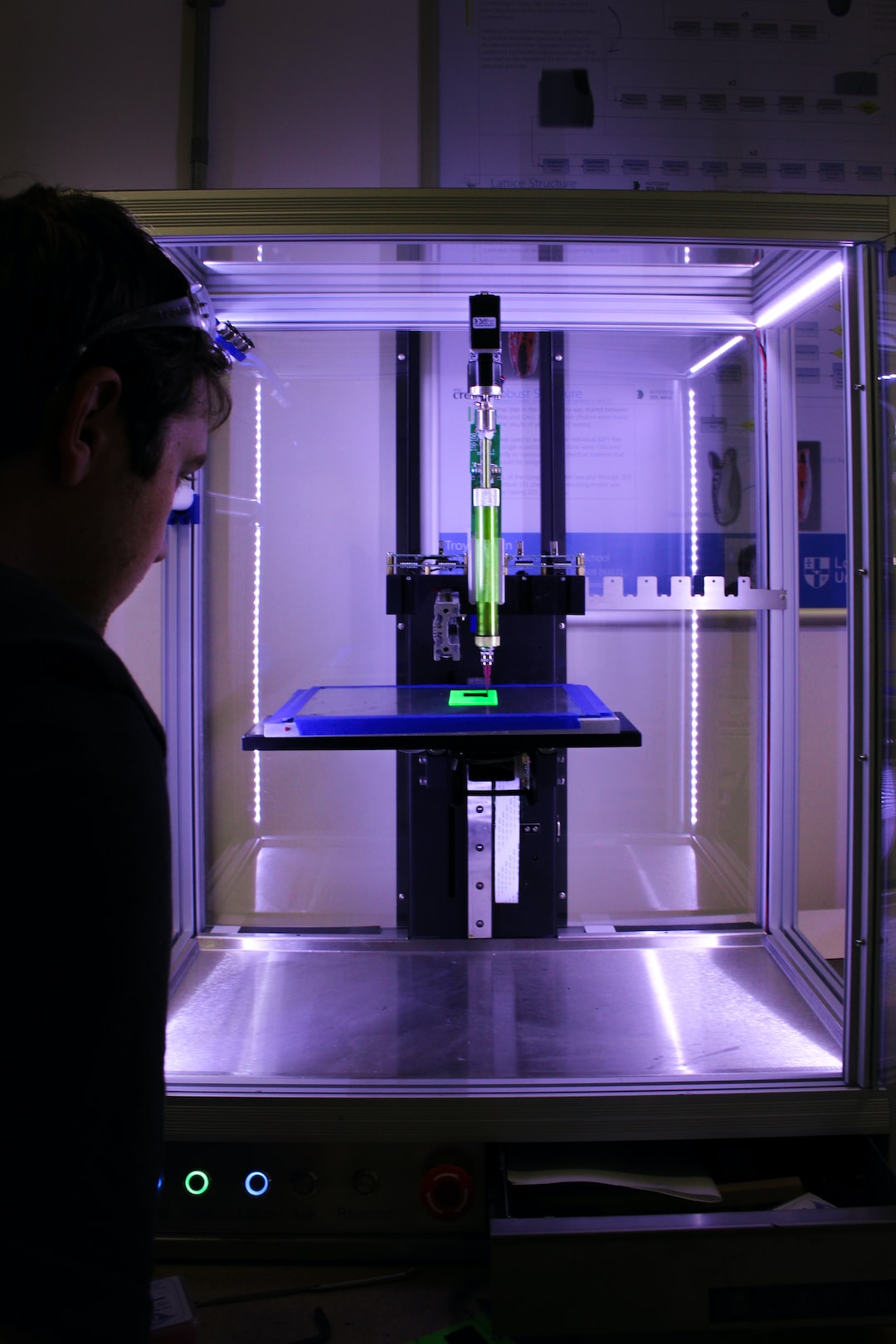

A smart factory is an advanced manufacturing facility that integrates IoT technologies to optimize processes, increase efficiency, and enhance productivity. By connecting machines, devices, and sensors, these factories create a network of interconnected systems that communicate and share data in real-time.

One of the key benefits of IoT integration in manufacturing is the ability to collect and analyze vast amounts of data. Sensors embedded in machinery and equipment can monitor performance, identify inefficiencies, and predict maintenance needs. This data-driven approach enables proactive decision-making, as potential issues can be addressed before they become significant problems, minimizing downtime and reducing costs.

Moreover, IoT integration allows for greater automation and control in the manufacturing process. For instance, production lines can be programmed to self-adjust based on real-time data, ensuring optimal performance and quality. This level of automation not only improves efficiency but also reduces the risk of human error, resulting in higher-quality products.

Smart factories also offer enhanced supply chain management capabilities. By connecting production processes with suppliers and customers through the IoT, manufacturers can gain real-time visibility into inventory levels, demand patterns, and delivery statuses. This enables more accurate forecasting, efficient resource allocation, and faster response times to customer demands.

The benefits of IoT integration in manufacturing extend beyond improving operational efficiency. It also paves the way for new business models and revenue streams. For instance, the availability of real-time data from smart factories enables manufacturers to offer value-added services such as predictive maintenance, remote monitoring, and product customization. These services not only generate additional revenue but also foster stronger relationships with customers.

However, the rise of smart factories also brings challenges and risks. As more devices and systems become interconnected, the issue of data security and privacy becomes paramount. Manufacturers must ensure that robust cybersecurity measures are in place to protect their systems from cyber threats. Additionally, given the reliance on connectivity, any network disruptions or system failures could have significant consequences on production and profitability. Therefore, manufacturers must invest in backup systems and contingency plans to minimize the impact of such incidents.

In conclusion, the rise of smart factories through IoT integration is transforming the manufacturing landscape. By harnessing the power of data and connectivity, these factories are driving operational efficiency, improving product quality, and enabling new revenue streams. Nonetheless, manufacturers must be mindful of the challenges and risks associated with this technology to ensure the continuity and security of their operations. As IoT continues to evolve, so will smart factories, paving the way towards a more connected and digitized future for the manufacturing industry.