The Importance of Quality Control in Manufacturing

Quality control is an essential aspect of manufacturing that ensures products meet the required standards and specifications. It plays a significant role in ensuring customer satisfaction and maintaining a good reputation for the company. Manufacturing processes involve several stages, from raw material acquisition to the finished product. Throughout this process, quality control ensures that each stage is monitored and inspected to detect any defects or anomalies that may affect the final product’s quality.

There are numerous reasons why quality control is vital in the manufacturing industry. Firstly, it helps to identify and rectify any deviations or issues in the manufacturing process. By conducting regular inspections and tests, manufacturers can pinpoint any areas that need improvement and take appropriate action. This proactive approach prevents the production of faulty products and increases overall efficiency.

Secondly, quality control safeguards against potential recalls and customer complaints. If a product is released into the market without proper inspections, there is a risk that it may have defects or fail to meet certain safety standards. This can result in customer dissatisfaction, and in severe cases, may even cause harm or injury. Recalls can be costly and damaging to a company’s reputation. Therefore, quality control measures are necessary to prevent such situations from occurring.

Moreover, quality control is crucial in maintaining consistency and uniformity in the manufacturing process. It ensures that each unit produced adheres to the same quality standards, resulting in a standardized and reliable product. Consistency is especially important for industries that produce goods in large quantities, such as the automotive or food sectors. Customers expect the same level of quality and performance from each product they buy, and quality control assures this consistency.

Furthermore, quality control plays a significant role in reducing waste and increasing cost-effectiveness. By detecting and eliminating defects early in the manufacturing process, manufacturers can avoid unnecessary expenses associated with rework or disposal of faulty products. Quality control also helps to identify areas where improvements can be made to minimize waste and improve efficiency, resulting in cost savings for the company.

Quality control also supports continuous improvement and innovation in the manufacturing industry. By analyzing data collected during the quality control process, manufacturers can identify trends and patterns that provide valuable insights into potential enhancements. This data-driven approach enables companies to make informed decisions that lead to improved processes, better products, and ultimately, increased customer satisfaction.

In today’s global marketplace, where competition is fierce, quality control is vital for companies looking to stay ahead. With globalization, manufacturers face increasing pressure to lower costs and deliver products in a shorter timeframe while maintaining high quality. Quality control helps manufacturers achieve this delicate balance by ensuring that each product meets the required specifications without compromising on quality.

Implementing an effective quality control system requires careful planning, documentation, and training. It involves setting standards, creating inspection procedures, and establishing checkpoints throughout the manufacturing process. Quality control personnel are responsible for conducting tests, inspections, and audits to ensure that products meet the desired quality standards.

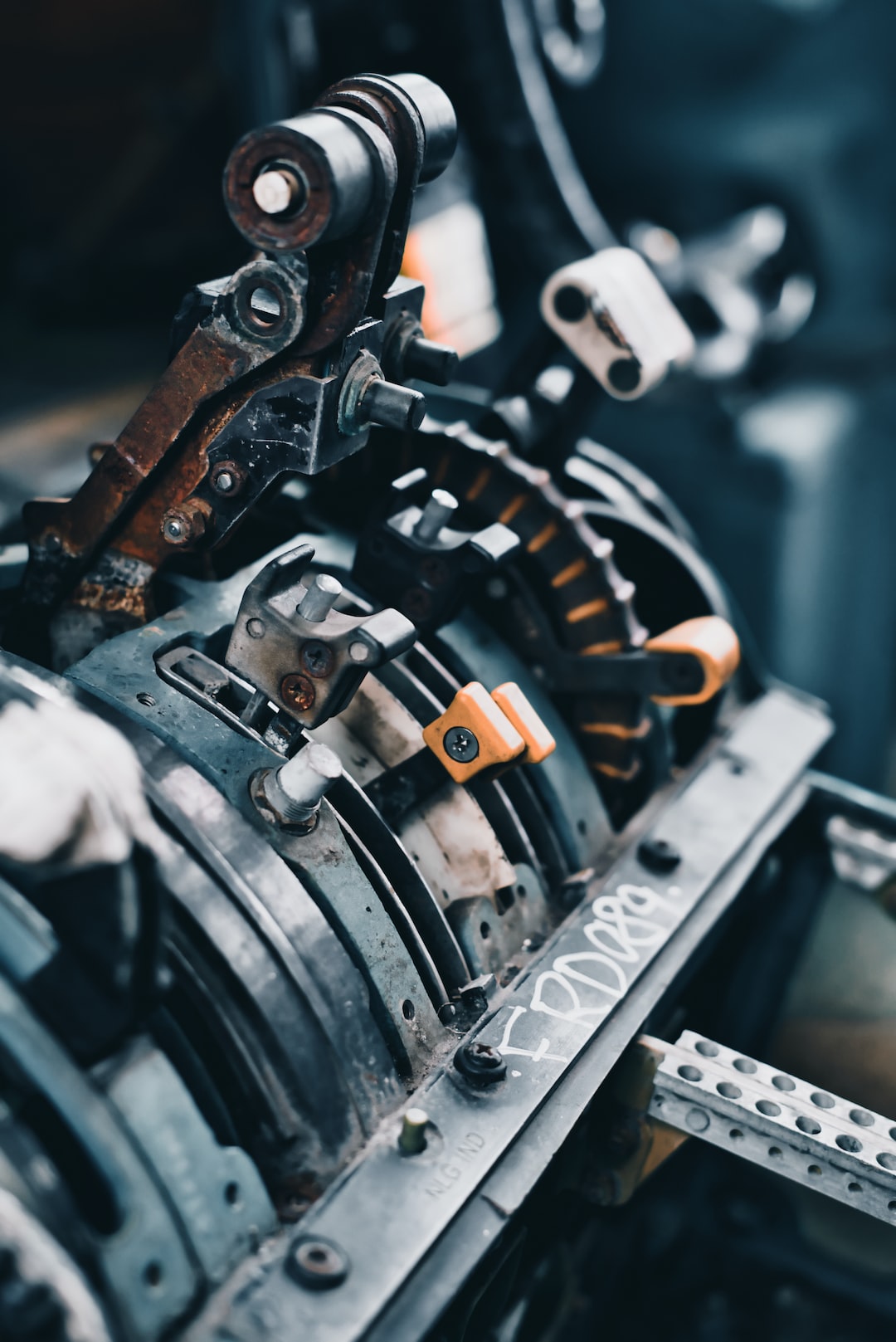

Advanced technologies, such as automation and artificial intelligence, are also revolutionizing quality control in manufacturing. These technologies enable faster and more accurate inspections, reducing human error and increasing efficiency. For example, robotic arms equipped with sensors can perform complex inspections and identify defects that might go unnoticed by human inspectors.

In conclusion, quality control plays a pivotal role in manufacturing. It is essential for ensuring customer satisfaction, maintaining a good reputation, and improving cost-effectiveness. By implementing effective quality control measures, manufacturers can produce consistent, reliable, and high-quality products. In today’s competitive market, companies that prioritize quality control are more likely to succeed and thrive, as they can meet the ever-increasing demands and expectations of consumers.